Please note that most orders for mirrors and autocue glasses are cut and made to customers exact requirements and the price lists below offer a range of possible sizes for price comparison. It's usually possible to supply directly from stock, but not in all instances. If you need an item by a specific date, please make us aware of the situation when ordering.

If there were to be a delay of more than a few days in sending your order, we would call you and take payment only when goods are ready to send

| Size | Price (£) | p&p |

|---|---|---|

| 6" x 8" (150x200mm) | 28.00 | 12.00 |

| 8" x 8" (200x200mm) | 38.00 | 16.00 |

| 8" x 10" (200x250mm) | 48.00 | 20.00 |

| 9" x 12" (225x300mm) | 56.00 | 24.00 |

| 12" x 12" (300x300mm) | 68.00 | 24.00 |

| 12" x 14" (300x350mm) | 80.00 | 28.00 |

| 12" x 16" (300x400mm) | 92.00 | 28.00 |

| 14" x 16" (350x400mm) | 100.00 | 30.00 |

| Size | Price (£) | p&p |

|---|---|---|

| 14" x 20" (350x500mm) | 120.00 | 32..00 |

| 16" x 18" (400x450mm) | 128.00 | 32.00 |

| 16" x 20" (400x500mm) | 140.00 | 36.00 |

| 20" x 20" (500x500mm) | 156.00 | 50.00 |

| 20" x 24" (500x600mm) | 170.00 | 50.00 |

| 20" x 28" (500x700mm) | 190.00 | TBA |

| 20" x 30" (500x760mm) | 240.00 | TBA |

| 27" x 36" (735x915mm) | 340.00 | TBA |

Standard glass prices above are manufactured from Pilkington best quality float glass. We vacuum coat the reflective coating so the glass size, thickness and reflection level can be to your requirements.

SEE BELOW for enhanced reflection glasses with anti-reflective rear coatings Also manufactured from high quality float glass, they will not be Pilkington brand substrate.

These are used as ultimate quality tele-prompter glasses and Peppers Ghost ( Holographic Effect ). beam-splitter glasses.

We are in a position to supply standard replacement glasses for all designs of commercial studio prompting units.

As an xample of cost replacement glasses as supplied for BDL Autoscript units are listed below.:

| Vitec Code | Price (£) | |

|---|---|---|

| Large Metal (2mm) Glasses | RGFH-S | 125.00 |

| Extra Extra Wide Angle (3mm) - XXW Glasses | RGFH-XW | 240.00 |

| Extra Wide Angle (3mm) - XWA Glasses | RGMH-W | 200.00 |

| Standard (3mm Truncated Corners) - GLA1 Glasses | RGMH-S | 140.00 |

| Conference (3mm) - CG Glasses | CNG | 90.00 |

| Available from stock. Packing, delivery and VAT extra. | ||

| Size | Price (£) | p&p |

|---|---|---|

| 6" x 8" (150x200mm) | 42.00 | 12.00 |

| 8" x 8" (200x200mm) | 48.00 | 16.00 |

| 8" x 10" (200x250mm) | 58.00 | 20.00 |

| 9" x 12" (225x300mm) | 70.00 | 24.00 |

| 12" x 12" (300x300mm) | 80.00 | 24.00 |

| 12" x 14" (300x350mm) | 94.00 | 28.00 |

| 12" x 16" (300x400mm) | 106.00 | 28.00 |

| 14" x 16" (350x400mm) | 120.00 | 30.00 |

| Size | Price (£) | p&p |

|---|---|---|

| 14" x 20" (350x500mm) | 160.00 | 32.00 |

| 16" x 18" (400x450mm) | 160.00 | 32.00 |

| 16" x 20" (400x500mm) | 170.00 | 36.00 |

| 20" x 20" (500x500mm) | 190.00 | 50.00 |

| 20" x 24" (500x600mm) | 200.00 | 50.00 |

| 20" x 28" (500x700mm) | 240.00 | TBA |

| 20" x 30" (500x760mm) | 320.00 | TBA |

| 27" x 36" (735x915mm) | 400.00 | TBA |

General Information

Unless requested, otherwise:

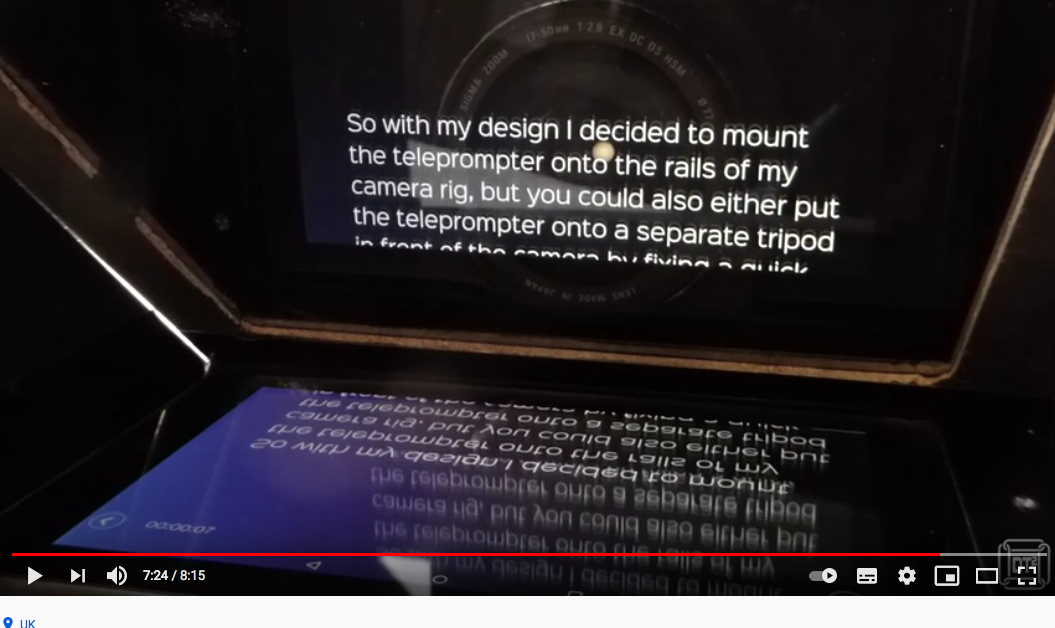

See one of our customer's home made teleprompter units. He is an accomplished DIY'er and whilst you may be looking for something simpler his video gives you the full picture on how to make one.

To see the video click on the image above

The standard glass uses a high quality, permanent, semi-reflective titanium layer. After coating in the vacuum chamber the glass is fired to 400C to oxidise the titanium metal and produce a tough, transparent, semi-reflective layer.

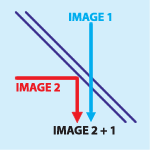

The amount of reflected light varies with the angle of reflection. Reflection level increases the greater the angle. Normally the glass is used at an angle of about 45°. The density and therefore the strength of reflection can be varied within a certain range during coating. Clear un-coated glass will usually reflect about 15% of light at this angle. A thinly coated beam-splitter 20% - 25%. The strongest reflection available with this coating is about 40%.

Autocue machines usually work with a glass reflecting about 30% of light. This ensures a bright image reaches the camera. The secondary reflection from the back surface is faint and unobtrusive for most uses. The titanium coating absorbs some light and the glass itself about 5% more, so the secondary reflection is greatly reduced. Some manufacturers of studio equipment use standard glasses, others offer a glass with an anti-reflective coating on the rear surface. This reduces the faint secondary reflection even further.

Autocue glasses are usually referred to as having a 30:70 ratio, or 35:65 ratio, indicating the relative amounts of light being reflected and/or passed to the camera. Other uses are for Conference Glasses, where a camera is not involved. In this case the reflection can be increased to the 35% plus mark, as the slight neutral tint of the glass does not detract from its use. When used as a 'Peppers Ghost Glass' it allows images from two directions to be combined into one. Where the user has control over the lighting, the exact split between reflection and transmission is not too important.

A greater consideration is the types of images being combined. With high contrast light and dark tones, the very best result will be obtained with a strongly reflecting glass having an anti-reflective coated rear face. This would be important for 3D Camera Devices. Used in other configurations it allows images to be projected and re-photographed, filmed, videoed and allows on-axis lighting for photography. The anti-reflective layer is tough and will not wear with normal cleaning. Likewise, because it is baked on to the glass at a temperature of 400C the reflective layer cannot wear away and may be cleaned and treated as a normal glass surface